Why professional testing for compatible iPhone batteries matters — and why you should demand it!

When it comes to iPhone repairs, there’s hardly any component as important (and potentially dangerous) as the battery.

Behind every high-quality lithium cell is a series of extensive laboratory tests that ensure performance, safety, and reliability. Unfortunately, many aftermarket suppliers skip or even falsify these tests — putting both technicians and customers at risk.

At 2Service / Mobileparts.shop, we take the quality of our compatible iPhone batteries very seriously. Let’s take a closer look at the four most important tests that we (and any trustworthy supplier ) perform, and what these tests reveal about the cells you install every day.

Disclaimer: These tests apply to the iPhone-compatible batteries sourced by Mobileparts.shop, categorized as Compatible. This blog does not apply to genuine iPhone batteries, which are also available in our webshop.

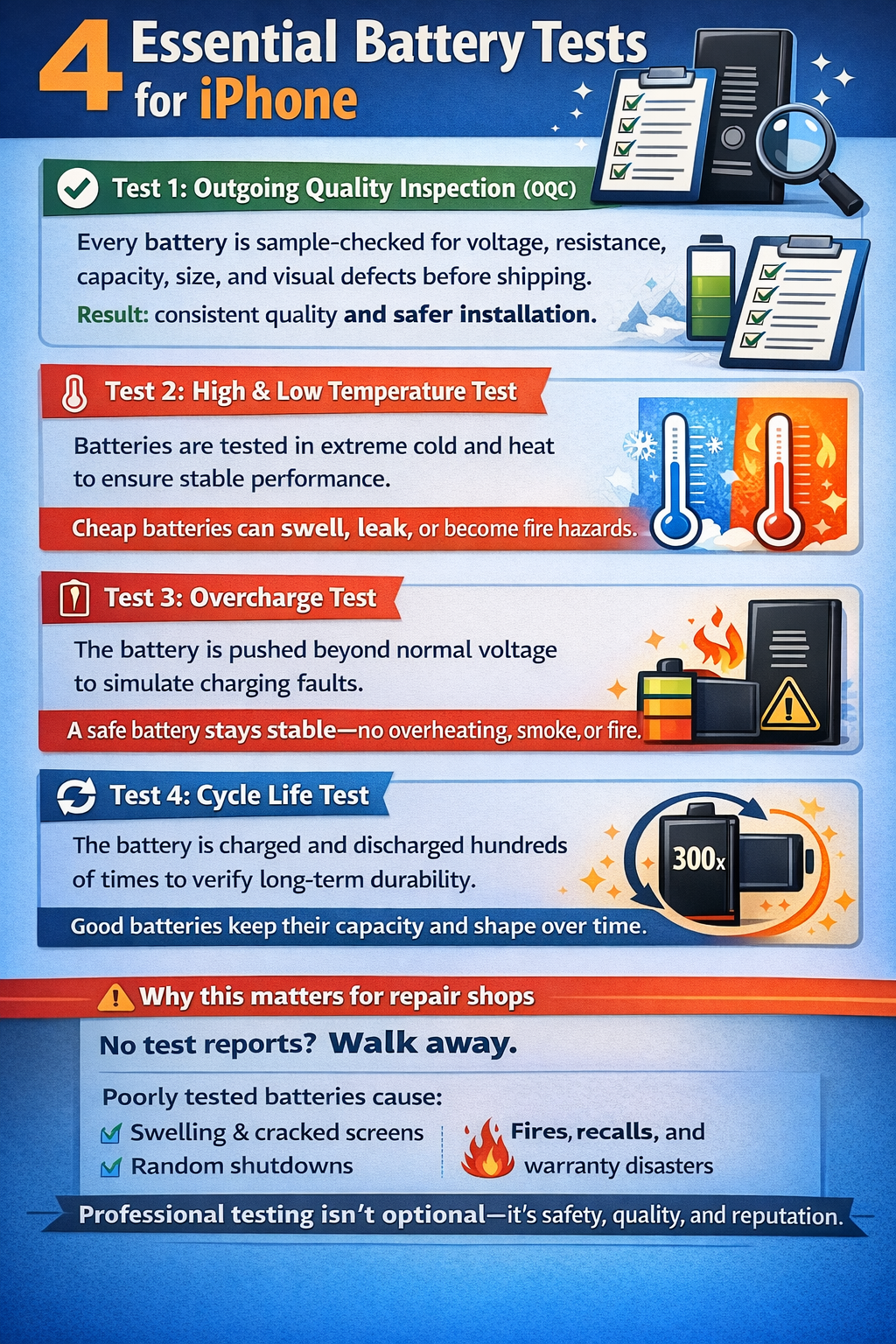

Test 1: Outgoing quality inspection — The foundation of trust

Before any compatible battery for iPhone leaves the factory, it undergoes an Outgoing Quality Inspection (OQC).

This is a sample-based check of voltage, internal resistance, capacity, dimensions, and visual appearance.

For example, in one of our recent inspection reports (Model 44448), every tested cell showed:

- Stable voltage around 3.99 V

- Low internal resistance (~27 mΩ)

- Consistent capacity (~2985 mAh)

- No swelling, scratches, or contamination

These results prove that the cells were properly balanced, assembled, and safe for shipment.

Without this check, hidden defects or manufacturing variances can easily cause swelling, overheating, or early failure once installed in a phone.

Test 2: High & low temperature discharge test — performance under stress

Smartphones are used everywhere, from freezing winters to hot dashboards in summer.

That’s why responsible manufacturers perform temperature discharge testing.

In this test, cells are fully charged and then discharged at various temperatures:

- –20 °C: 56% capacity retained

- –10 °C: 68% capacity retained

- 55 °C: 101% capacity retained

- 85 °C: 98% capacity retained

This shows that a well-made cell keeps working safely even in extreme conditions.

Low-cost, untested batteries often expand, leak, or even vent gas under high heat, which is a fire hazard inside compact phone housings.

Test 3: Overcharge test — safety comes first

Even the best smartphones can experience charging irregularities, especially after third-party repairs.

An Overcharge Test simulates this by pushing the battery beyond its rated voltage (4.35 V) while monitoring temperature and reaction.

During our safety validation:

- Cells reached only ~46 °C (well within limits)

- No smoke, fire, or leakage occurred

- The cells returned to normal state after cooling

This test proves that internal protection circuits and chemistry can handle overvoltage safely, a key safeguard against thermal runaway or explosions.

Skipping this test means gambling with your customers’ safety and your reputation.

Test 4: Cycle life test — proving long-term reliability

Battery life isn’t just about one charge — it’s about hundreds of cycles.

A cycle life test repeatedly charges and discharges the cell, checking how much capacity remains over time.

In one of our verified test results:

- After 300 full charge/discharge cycles, the cell still had 95% capacity

- No swelling, heat rise, or performance drop was observed

That’s the kind of endurance you expect from OEM-grade batteries and the kind your customers deserve.

⚠️ Why this matters for every repair shop

If your supplier cannot provide authentic test reports like these — walk away.

A lithium battery is not just a component; it’s a chemical energy system.

Without proper verification, it can become a fire source inside your customer’s phone.

Poorly tested cells are the root cause of:

- Swelling and cracked screens

- Random shutdowns

- Meltdowns during charging

- Workshop fires and warranty disasters

Professional testing isn’t optional, it’s the difference between safe repair and serious liability.

💡 What you should demand from your supplier

Before buying or installing replacement batteries, always ask for:

- Outgoing Quality Inspection Report (voltage, resistance, capacity)

- Temperature Discharge Test Report

- Overcharge Safety Report

- Cycle Life Test Report

If your supplier hesitates, it’s a red flag. Genuine factories will proudly share this data, it shows they care about safety, reliability, and engineering quality.

Final thoughts

Every professional repair center should hold its suppliers to the same standards used by OEM manufacturers. Battery testing isn’t bureaucracy, it’s engineering safety.

By demanding proper test documentation, you protect your customers, your business, and the entire reputation of the repair industry.

Professional repairs start with professional parts.

If you want to work with suppliers who properly test and document every battery, make sure you partner only with certified and transparent distributors.

It won’t surprise you to hear that we, Mobileparts.shop have completed all the tests and made them available for you to review.

You can ask for them by sending us an email: sales@2service.nl.

Disclaimer: These tests apply to the iPhone-compatible batteries sourced by Mobileparts.shop, categorized as Compatible. This blog does not apply to genuine iPhone batteries, which are also available in our webshop.

Related articles

-

Parts Technical info

Parts Technical infoNew: Pulled iPhone 16/17 front cameras – directly calibratable without an additional flex

Discover the new iPhone 16/17 front cameras that are pre-tested for calibration, making repairs faster and simpler for technicians.

Read more -

Parts Technical info

Parts Technical infoHow to recognize an original JK OLED display? – 6 key checkpoints

Learn to identify authentic JK displays with six key tips and ensure you're always using genuine products from Mobileparts.shop, Europe's official JK distributor.

Read more -

Parts Technical info

Parts Technical infoInside the battery: How Mobileparts.shop ensures top-quality compatible batteries for iPhone

Mobileparts.shop ensures top-quality iPhone and iPad batteries through a meticulous production and multi-step testing process, focusing on safety, performance, and longevity, ultimately providing...

Read more