Inside the battery: How Mobileparts.shop ensures top-quality compatible batteries for iPhone

As a smartphone repair professional, you know that the battery is at the heart of every successful repair. It’s not just about getting a device to turn on again — it’s about ensuring safety, performance, and longevity for your customers. At Mobileparts.shop, we understand this responsibility, which is why every iPhone and iPad battery goes through a meticulous, multi-step production and testing process before it ever reaches your workbench.

Let’s take a look behind the scenes at how our batteries are made and why that makes a difference for you.

Disclaimer: These tests apply to the iPhone-compatible batteries sourced by Mobileparts.shop, categorized as Compatible. This blog does not apply to genuine iPhone batteries, which are also available in our webshop.

- Selecting the right cells

Every great battery starts with the right foundation: pure cobalt A-grade cells. These premium cells deliver better energy density, stability, and durability — ensuring consistent performance over hundreds of charge cycles.

A pure cobalt A-grade cell is a high-quality lithium-ion battery cell that uses cobalt as the main component in its cathode material, known for its excellent energy density, stability, and reliability.

Pure cobalt: The cathode primarily contains cobalt (often in lithium cobalt oxide, LiCoO₂ form), which provides high energy storage.

- Batch testing for safety and performance

Before moving forward, small batches of cells are put through rigorous tests.

They are overcharged, over-discharged, and exposed to extreme temperatures (above 60°C and below -20°C). Even after 500 full charge cycles, each cell must retain more than 80% of its original capacity without swelling or exploding.

This process guarantees that only the most reliable cells move forward to the next stages.

- Measuring internal resistance

Next, every cell’s internal resistance, current, and voltage are carefully measured. Lower internal resistance means higher efficiency and longer battery life — a key factor in keeping repairs reliable and customers happy.

Resistance in a battery refers to the opposition to the flow of electric current within the cell. It’s caused by the materials inside the battery (electrodes, electrolyte, and connectors).

Battery resistance determines how efficiently a battery can deliver power — lower resistance means less energy loss, less heat, and better performance.

- Visual inspection and quality control

No physical flaw goes unnoticed. Each cell is inspected for dents, scratches, leaks, or other imperfections. If the battery doesn’t look perfect, it doesn’t pass.

- Checking the Battery Management System (BMS)

Using precision microscopes, technicians check every protection board connector to ensure there are no missing or damaged components. This system is critical — it monitors temperature, current, and voltage to keep the battery safe during use.

A Battery Management System (BMS) is an integrated circuit or set of electronic components designed to measure and control key parameters of a battery pack—such as voltage, current, temperature, and state of charge (SOC)—to maintain performance, extend lifespan, and prevent hazardous conditions like overcharging, over-discharging, overheating, or short-circuiting.

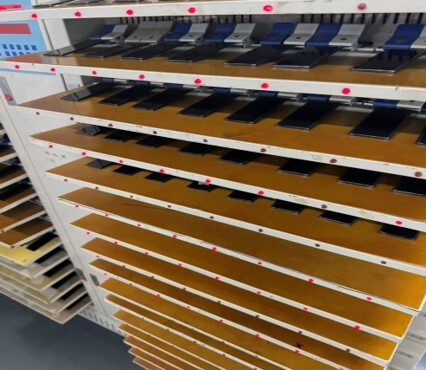

- Consistent performance through testing

Each BMS is tested to make sure performance parameters match across the entire batch, ensuring stable standby current and reliable operation in real-world conditions.

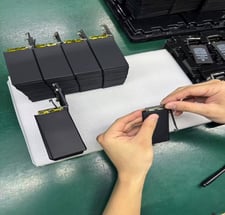

- Laser welding for precision and stability

Laser welding joins key components with high conductivity and low resistance, which minimizes energy loss and ensures a stable voltage output — essential for optimal device performance.

- Insulation and protection

The connector side of every battery is insulated to prevent short circuits. A protective bracket is then installed to improve both safety and appearance. Finally, the BMS is wrapped to prevent accidental contact between conductive parts inside the device.

Insulation in a battery refers to the protective material or layer that prevents electrical contact between conductive parts.

- Final product testing

Before packaging, every finished battery is tested for:

- Capacity (current, full charge, and design)

- Health and cycle count

- Temperature stability

- Connector reliability

Only batteries that meet all these benchmarks are approved for sale.

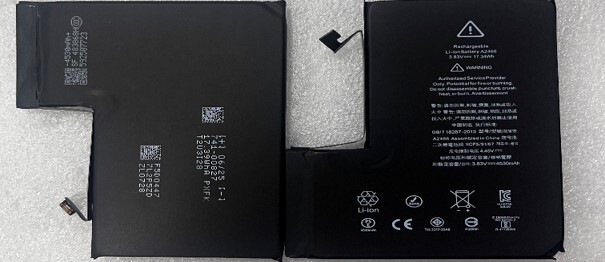

- Labeling and traceability

Each battery receives a printed label with clear identification and technical details — so you know exactly what you’re installing and can trust its origin and quality.

Why this matters for repair professionals

By choosing Mobileparts.shop batteries, you’re not just buying a replacement — you’re buying peace of mind. Every battery has been tested far beyond basic standards to ensure that when you install it, it performs just like the original, safely and reliably.

For you, this means fewer returns, fewer risks, and more satisfied customers who trust your work.

Related articles

-

Parts Technical info

Parts Technical infoWhy professional testing for compatible iPhone batteries matters — and why you should demand it!

Learn how Mobileparts.shop ensures top-quality iPhone batteries through rigorous testing done by suppliers, safeguarding your repairs and customer safety.

Read more -

Parts Technical info

Parts Technical infoNew: Pulled iPhone 16/17 front cameras – directly calibratable without an additional flex

Discover the new iPhone 16/17 front cameras that are pre-tested for calibration, making repairs faster and simpler for technicians.

Read more -

Parts Technical info

Parts Technical infoHow to recognize an original JK OLED display? – 6 key checkpoints

Learn to identify authentic JK displays with six key tips and ensure you're always using genuine products from Mobileparts.shop, Europe's official JK distributor.

Read more